Product Description:

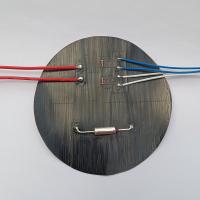

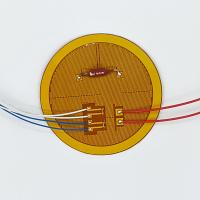

9*37mm Polyimide Ultra-thin Flexible Bendable Electric Film Heater:

Pi heaters (also known as flex heater) have the same function as

silicone mat heaters except they are much thinner (under 0.3mm) and

more flexible. These custom-made heaters can be built with similar

watt densities and can operate at similar temperatures as silicone

heaters.

They are constructed using thin polyimide sheets as insulation with

the heating element laminated inside. Advanced circuit imaging and

printing gives builders the flexibility to distribute wattage and

create many different heat patterns within the same space. It is a

high-temperature flexible heating element with excellent dielectric

properties capable of operating environments between -40 degree

celsius to 300 degree Celsius.

Technical Parameters:

| Attribute | Value |

|---|

| Warranty | 3 Years |

| Resistance Tolerance | +/-5% |

| Temperature Sensor | Thermocouple Or RTD |

| Lead Wire | As Requested |

| Dielectric Strength | 220V AC For 1 Minute |

| Type | Flexible Heater |

| Condition | New |

| Thickness | 0.1mm-0.5mm |

| Size | Customized |

| Material | Polyimide |

Applications:

1. “professional OEM manufacturer”has more than 50 independent

technology patents and trademarks.2. Carefully selected materials,kneading and pressure resistance.

3. Fast heating, lock the temperature.

4. Even heating, good maneuverability, accurate temperature

control.

5. Thermal conductivity increased by 20%, energy saving by 20%,

increased battery life.

6. It has a wide range of applications.

Kapton® Heaters Feature:

They boost excellent physical and electrical properties – results in thermal stability over a wide temperature range.

Transparent polyimide material – that allows inspection of internal details. Opaque version also

available.

Resistance of radiation and fungus – can be used in a wide range of applications.

Rugged, reliable, accurate, and moisture/chemical-resistant

They can be easily bonded or adhered to many surfaces or other

system parts.

Packing and Shipping:

Packaging and Shipping for Custom Polyimide Heaters

Here is our standard packaging and shipping process for custom

polyimide heaters:

- Step 1: Each heater is individually wrapped in a protective layer

to prevent scratches and other surface damages.

- Step 2: The heaters are then placed in a sturdy cardboard box to

provide additional protection.

- Step 3: The box is filled with cushioning material, such as bubble

wrap or foam, to prevent any movement during transit.

- Step 4: The box is sealed and labeled with the product name,

quantity, and any special handling instructions.

- Step 5: The packaged heaters are then loaded onto a secure shipping

container.

FAQ:

1. who are we?We are based in Guangdong, China, start from 2014,sell to Eastern

Asia(40.00%),North America(25.00%),South America(15.00%). There are

total about 11-50 people in our office.2. how can we guarantee quality?The factory area is large, the production capacity is guaranteed,

and the industry experience is many years;It has a number of

experienced professionals, equipped with complete sets of excellent

equipment;Cooperate with customers pre-sale, sale, after-sales service.3. Whether can order online directly?A: You should contact with us providing dimension, CAD drawing,

voltage and power, material, thickness and whether you need gum or

wire.4. what services can we provide?Accepted Delivery Terms:A. For samples: 8~12 days after paymentB. For large qty: 10~15 days after paymentC. Door to door service,using FedEx;